By kirk

•

April 6, 2025

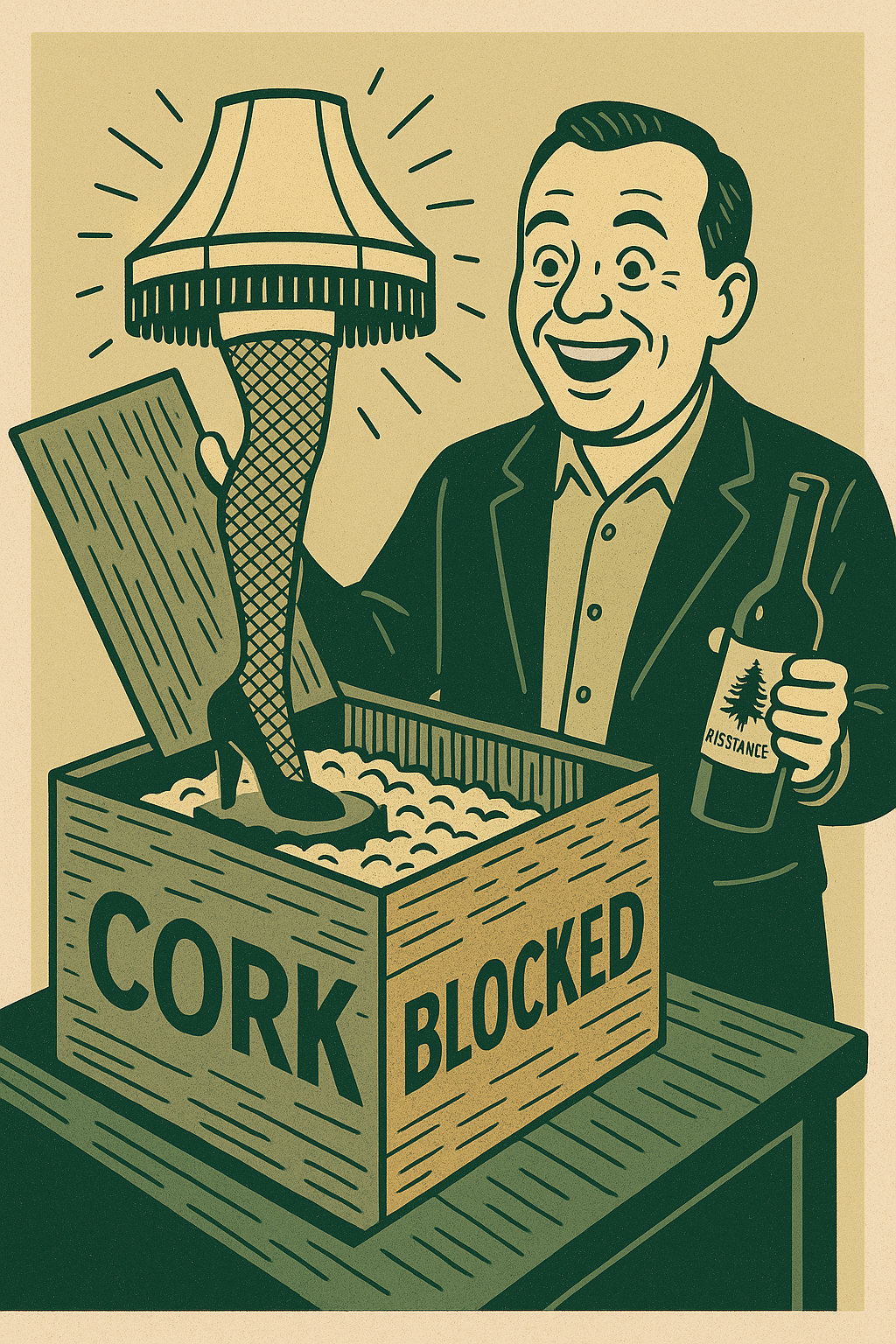

They say that making wine is half science experiment, half black magic, and a whole lot of patience. Sometimes, though, the magic misfires and we end up with bizarre aromas and flavors that hijack your taste buds quicker than your grandma’s perfume. Here at Resistance Wine Company, we’ve walked down that road a few times—by choice or by accident—and we’ve got stories to tell. Let’s celebrate the top ten wine flaws, from a winemaker’s perspective. They’re educational, a bit tragic, and definitely comedic. Because hey, if you can’t laugh at your flawed wine, can you even call yourself a winemaker? 1. Oxidation: When Your Wine Ages Faster Than You Do What Went Wrong: Oxygen is both a friend and foe. A little aeration during fermentation? Great for yeast health. But let the oxygen waltz in uncontrolled and you’ll end up with a wine that tastes like stale nuts and old fruit salad. In the cellar, if you’re not paying attention—loose barrel bungs, sloppy transfers, or leaving that half-finished bottle on the counter for two days—oxidation is right there, waiting to pounce. What You’ll Taste & Smell: Flat, dull flavors of overripe apples, sherry-like nuttiness, and a browning color that might remind you of your mom’s leftover gravy. The Resistance Take: Let’s just say if your wine is turning brown and tasting like a liquid thrift store, it’s not going to spark a revolution. 2. Cork Taint (TCA): The Enemy Lurking in the Cellar What Went Wrong: Cork taint is often caused by a compound called TCA (2,4,6-trichloroanisole). It can live in corks, barrels, winery walls, or basically anywhere that’s touched chlorinated cleaning products. When it sneaks into the bottle, your once-vibrant wine turns into a damp cardboard fiasco. What You’ll Taste & Smell: Musty basement, wet newspaper, that smell you get when your dog’s been out in the rain for too long. The Resistance Take: We use a composite cork – it is more sustainable and certified free of TCA. Left over cork bark is ground up and glued back together with a polymer that allows for an optimal level of oxidation over time without the risk of TCA. 3. Brettanomyces (Brett): Funky Barnyard Groove What Went Wrong: Brett is a rogue yeast that sets up camp in barrels, winery floors, and equipment that didn’t get a proper cleaning. It’s not always a deal-breaker—some folks actually like a bit of that “rustic” edge in red wines—but cross the line, and your bottle graduates from “intriguing funk” to “barnyard meltdown.” What You’ll Taste & Smell: Horse stable, sweaty saddle, cloves, Band-Aids, and that oh-so-funky vibe some of us love…until we don’t. The Resistance Take: A little rebellious funk can be cool. But if “yee-haw barn party” is all you can taste, your wine might have staged a mutiny. 4. Volatile Acidity (VA): The Sharp Vinegar Slap What Went Wrong: Acetic acid bacteria munch on wine’s sugars (or even ethanol) and release acetic acid. Sometimes, a bit of VA adds complexity, but let it spiral out of control and you’ve got vinegar for dinner. What You’ll Taste & Smell: Think pickles, nail polish remover, or that pungent whiff you get when you open a fresh bag of salt-and-vinegar chips. The Resistance Take: If your wine is strong enough to clear your sinuses, you might want to wave the white flag. 5. Reduction (Sulfur Compounds): Rotten Eggs and Beyond What Went Wrong: In low-oxygen environments (like certain stainless-steel fermentations), sulfur compounds can develop. This can lead to those charming aromas of boiled eggs, burnt rubber, or even a skunky vibe. What You’ll Taste & Smell : Burnt matches, onion, and (best case scenario) flinty minerality. Worst case? Think rotten eggs simmering on a hot day. The Resistance Take: Some of us actually like a hint of that flinty edge—just not enough to remind us of the local sulfur springs. Resist the urge to oversulfite, and keep that oxygen at a healthy minimum. 6. Refermentation in Bottle: The Surprise Sparkle Attack What Went Wrong : Residual sugar plus leftover yeast equals a party in your bottle. If the wine wasn’t filtered or stabilized properly, it can keep fermenting. The result? Bubbles you never asked for—or worse, corks popping off like fireworks in your cellar. What You’ll Taste & Smell: A fizziness on your tongue, sometimes a yeasty note like bread dough. Could be fun if you meant to make a pét-nat. Not so fun when your cork hits the ceiling at 2 a.m. The Resistance Take: If you’re popping bottles spontaneously in the basement, it might be time to ask, “Did the winemaker do the final math on this one?” The revolution isn’t supposed to start with your wine rack exploding. Many “natural” wines end up here. This is why we prefer to make “minimally invasive” wines. If things aren’t going perfect in the wine making – we will make small adjustments to make sure you have great tasting wine that won’t keep have a surprise fermentation going on in your bottle. 7. Smoke Taint: When Your Wine Takes Up Vaping What Went Wrong: Wildfires are heartbreakers for vineyards. Smoke compounds stick to grapes and later release as that ashy, acrid flavor in your finished wine. While some minimal exposure can add complexity, heavy smoke can push your wine into the “liquid campfire” zone. What You’ll Taste & Smell: Ash tray, BBQ pit, or an extinguished bonfire from last night’s party. The Resistance Take: We like a wine with some grit, but not when it tastes like you dropped your fruit in yesterday’s coals. 8. Hydrogen Sulfide (H₂S): The Not-So-Silent Stinker What Went Wrong: Winemakers may use sulfur-containing compounds to feed yeast or control unwanted bacteria. But if there’s not enough nitrogen or if fermentation gets stuck, H₂S can pop up like an unwelcome guest. What You’ll Taste & Smell: Rotten eggs, sewer gas, that unmistakable “something died in here” vibe. Sometimes it can blow off with a swirl or a decant, but not always. The Resistance Take: If you’re swirling like a maniac to chase away the funk but it clings on like a stage-five clinger, it might be time to accept defeat. 9. Mousy Off-Flavors: When Your Wine Crosses the Rodent Line What Went Wrong: Usually caused by certain spoilage yeasts or bacteria that produce compounds reminiscent of…mice. This flaw often appears after you’ve swallowed, leaving a weird stale-nutty/rodent-cage aftertaste. What You’ll Taste & Smell: You won’t detect it on the nose so much—it’s more of a back-palate horror that creeps in after you swallow. Think cheap cereal or, yes, hamster cage bedding. The Resistance Take: No one expects to taste hamster. Resist the squeak. Once it’s mousy, you’re better off practicing your spit bucket technique. 10. Heat Damage & Cooked Wine: The Vacation That Ruined the Bottles What Went Wrong: Maybe your wine sat on a hot loading dock or in the trunk of your car all day. Extreme temperature changes can “cook” wine, breaking down delicate aromas and leaving you with a jammy, stewed mess. What You’ll Taste & Smell: Overripe or jammy fruit, dull flavors, sometimes the cork can even push out from the bottle neck. The Resistance Take: Once it’s cooked, there’s no un-cooking it. If you wanted mulled wine, you’d have used a pot and some spices. Final Thoughts from the Resistance Sure, wine flaws can be a drag—or a hilarious cautionary tale. From oxidation fiascos to barnyard bedlam and accidental fizz, these are the top ten villains that can crash your vino party. Consider this your crash course in sniffing out and speaking up when something’s off. At Resistance Wine Company, we believe in marching to our own beat—but hopefully without the stench of rotten eggs or that stale basement vibe. Ready to learn more or want to join the cause for better, bolder bottles? Drop by our digital digs at www.resistancewineco.com and keep the revolution rolling—one well-made (and flaw-free) glass at a time.